The hydrodynamic behavior of water–polyethylene oxide (PEO) solutions under model flow conditions in hydroperforator jet-forming nozzles was investigated. Experimental results confirmed that, in the nozzle inlet region, PEO macromolecular coils can transition into a highly extended conformation. The ratio of the measured birefringence to its theoretical maximum reached 0.33, corresponding to approximately 60% uncoiling of macromolecular chains. The energy potential of high-velocity jets formed from water–PEO solutions was studied at various polymer concentrations and nozzle discssharge pressures. Evaluation was conducted based on the penetration depth of the jet into a model casing string of an oil and gas well, the cement sheath, and the surrounding rock formation. Additional assessment was performed by measuring the impact force of the jet on a metal target mounted on a physical pendulum. A comprehensive investigation of the perforation process confirmed the mechanism underlying the high destructive capacity of polymer solution jets. It was shown that the exceptional cutting efficiency is due to the dynamic pressure exerted by the water–polymer jet, structurally “reinforced” by the highly stretched macromolecular chains formed in the nozzle inlet region. The assessment was carried out by measuring the impact force of the jet on a metal plate fixed to a physical pendulum. It was demonstrated that the high cutting efficiency of such jets is due to the destructive action of dynamic pressure from the water-polymer jet, which is structurally “reinforced” by highly stretched macromolecular chains in the nozzle's inlet region hydroperforator.

Keywords: Hydroperforator, Jet-forming nozzle, Jet quality, Casing string, Cement sheath, Rock, Macromolecular chain, Birefringence zone, Polymer solution jet

During drilling of oil and gas wells, the wellbore is stabilized with casing strings, which are cemented in the hydrocarbon-bearing formations. To enable oil and gas inflow from the formation into the well, a series of channels (holes) are created in the casing and the surrounding cement sheath. In practice, these perforations are most commonly achieved using cumulative (shaped charge) methods. However, this technique increases the risk of structural damage to the cement stone and casing, potentially leading to loss of formation isolation. To avoid this, a gentler method –hydroabrasive jet perforation – is employed, wherein a high-speed fluid jet with abrasive particles is used to cut through the materials. This type of jet can create deep channels in the casing, cement sheath, and rock, ensuring reliable communication between the wellbore and the reservoir.

Experience with hydroabrasive jet perforation in oil and gas wells has demonstrated significant advantages over other perforation methods, such as cumulative charges. However, this technique has a notable drawback – severe hydroabrasive wear of the internal surfaces of tubing, fittings, and other equipment involved in fluid preparation, transport, and application. This wear causes an increase in nozzle diameter and changes its profile, gradually reducing the jet speed, which in turn impairs channel formation and increases overall perforation time. It also necessitates more frequent nozzle replacements and associated tripping operations. Another disadvantage is the deep penetration of sand particles into the rock, which worsens reservoir productivity. These issues collectively increase the energy and resource intensity of the hydroperforation process.1,2

In hydroperforation, the cutting element is a high-speed fluid jet. The ability of the jet to deliver optimal hydrodynamic performance – which determines maximum efficiency and perforation quality at minimal energy costs – depends on the properties of the working fluid. Reducing the energy input is best achieved by lowering the working pressure at the nozzle, which aligns with technological requirements for oil and gas well perforation. Therefore, selecting the appropriate type and composition of the cutting fluid is a key concern in developing the perforation technology for casing strings.

One approach is to rely on the findings in1,3 which showed that small polymer additives to high-speed water jets increase their destructive capacity. Hence, the traditional hydroabrasive jet should be replaced with a jet of aqueous polymer solution.

The main objective of this work is to establish the mechanism of the perforation process of oil and gas wells using a high-velocity jet of polymer solution. Understanding the features of this mechanism is essential for the justification and selection of optimal perforation regimes.

Perforation experiments were conducted on laboratory test benches using a hydrostand based on the URG-3020 unit with a working pressure of up to 500 MPa as the high-speed liquid jet source. The target (obstacle) model was constructed as a "sandwich" comprising a 10 mm thick steel plate (Steel Grade D) representing the casing, a 20 mm thick concrete layer simulating the cement sheath, and core samples representing the rock. Total model thickness: 0.8 m. There was the possibility of controlling both the integral and differential parameters of material destruction processes using a water-polymer jet.1,4 Additional equipment included:

- 1. An opto-mechanical complex to study flow characteristics of polymer solutions in various nozzle configurations

- 2. A polarization-optical setup to analyze the dynamics of polymer macromolecules under model conditions in the inlet region of hydroperforator nozzles

- 3. Capillary and rotational viscometers for rheological measurements

- 4. A specialized hydrodynamic complex for investigating flow structure in jet-forming nozzles under model conditions.

The energy potential of the water-polymer jet was evaluated based on the measurable impact force of the jet on a steel (St3) plate equipped with strain gauges. The plate itself was mounted on a physical pendulum.

The polarization optical unit is mounted on a horizontally located optical bench and consists of a light source, a lens system for creating a parallel beam of light, a polarizing microscope, a light filter and a quarter wavelength plate. A schematic diagram of the installation can be found in18. The source of light is a mercury quartz lamp DRSh-250.

In the measurement of , the Becker compensator was used, the work with which was described in detail in Tatarskii VB (1965)5. The birefringence of the polymer solution subjected to uniaxial deformation, due to the optical anisotropy and orientation of segments of macromolecules, was calculated according to the formula:6

. (1)

Here – the index of refrection of the solution,

– the difference in the polarizabilities of the segments,

– their number per unit volume,

– the orientation parameter,

– the mean square cosine of the orientation angle

of the segments, measured relative to the principal direction of extension of the solution. The value

is defined as:

, (2)

where – the difference in the polarizabilities of the segment, caused by its own optical anisotropy;

and

– contributions to the difference between the polarizabilities of the segment, due to the anisotropy of the macroform of the molecular chain and the anisotropy of the segment itself (anisotropy of the microform) [7].

According to [8] for the maximum uncoiled state of the macromolecule, and

, (3)

where and

– index of refraction of polymer and solvent;

and

– coefficients, depending on the asymmetry of the shape of the segment;

– Avogadro's number;

– molecular mass of the segment;

– density of polymer.

To calculate for PEO solutions we took

[9];

;

;

;

[10]. The value

, equal to 5.4, was calculated with the help of the dependence of (

) upon

, given in [8], where

– the ratio of the length of the segment to its transverse dimension. It was found out that the contribution of the anisotropy of the microform of the PEO segment to the value

is about 36%.

Solutions of PEO with molecular weights of 4‧10⁶ and 6‧10⁶ were studied. The polymer concentration ranged from 0 to 0.1%. Solutions with fully dissolved PEO at the required concentration were prepared in dark glassware by diluting previously prepared 0.1% polymer solutions over a period of 7–8 days. Since aqueous solutions of PEO (as well as other polymers) significantly change their properties during long-term storage, a 0.05% potassium iodide additive was used as a stabilizer. This additive effectively prevents the aging of PEO in water and does not affect the hydrodynamic activity of the polymer.7-11

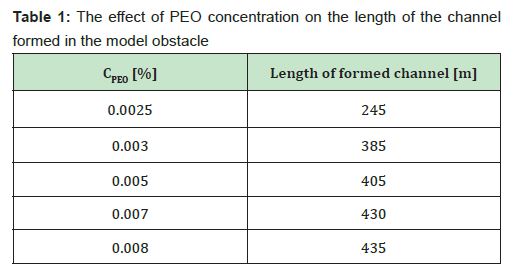

The results of channel formation in a model barrier by a water-polymer jet with a PEO concentration of 0.0025–0.008% and a molecular weight of 6∙10⁶, at an outflow pressure of 200 MPa, nozzle outlet diameter of 0.3∙10⁻³ m, and perforation time of 600 seconds are presented in Table 1.1 It can be seen that decreasing the PEO concentration below 0.003% significantly reduces the perforation efficiency. Increasing the concentration above 0.007% does not have a significant impact on the efficiency of channel formation in terms of the rational use of PEO.

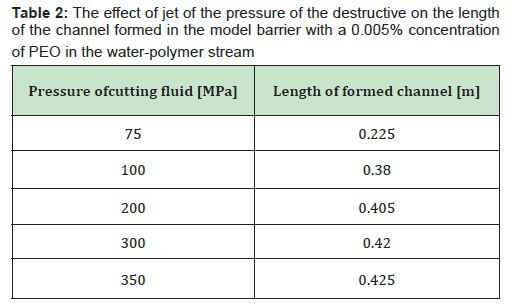

The tests were also performed with a concentration of PEO aqueous solution of 0.005%, but the pressure of the destructive fluid changed. These results are presented in Table 2.1

Decreasing the pressure below 100 MPa reduced the perforation efficiency, while raising it above 300 MPa caused a slight increase in the length of the channel; however, in a production environment there are technical difficulties in maintaining such high pressures.

A comparative analysis of the data presented in Tables 1 and 2 shows that a high-speed jet of aqueous PEO solution, within the selected concentration range and jet formation parameters, exhibits a high destructive capacity and, consequently, high efficiency in channel formation during oil and gas well perforation. This indicates the presence of a specific mechanism of channel formation in the barrier, which models the casing, cement sheath, and rock layer. Our current understanding of the perforation mechanism of oil and gas wells using hydrojet water-polymer perforation is far from complete.

The following section discusses experiments conducted to gain a deeper understanding of the mechanism behind the enhanced destructive capability of water-polymer jets. Particular attention is given to the advantages of using flow in model conditions of jet-forming nozzles, as this setup enables detailed investigation of the interaction between macromolecules and the hydrodynamic field. This, in turn, provides the basis for studying the specific features of the perforation process under strictly controlled conditions, which significantly increases the reliability of the obtained results.

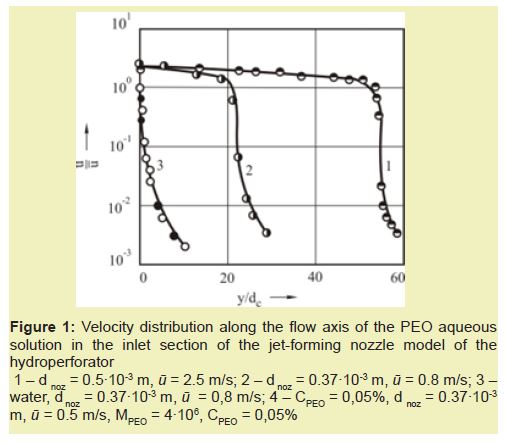

Figure 1 shows the results obtained using a laser Doppler anemometer, indicating the velocity development along the axis of the flow of an aqueous PEO solution in the inlet section of a model hydroperforator nozzle in dimensionless coordinates. For an aqueous PEO solution in pre-critical flow regimes, the axial velocity distribution is practically the same as that of water (curve 3 and points 4). In supercritical flow regimes, a significant deformation of the curves characterizing the development of axial velocity is observed (see curves 1 and 2). These curves exhibit at least two segments with a linear change in velocity.

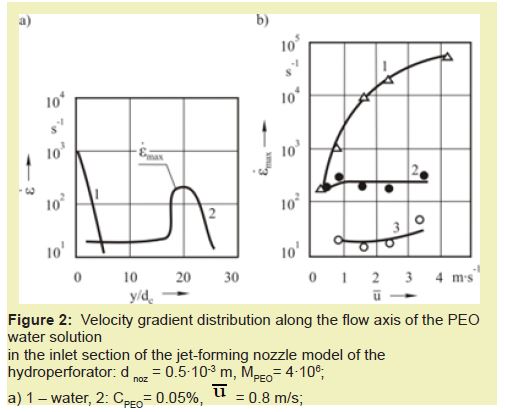

Using the velocity distributions along the flow axis of an aqueous PEO solution in the inlet section of the nozzle, the distributions of their gradients were obtained Figure 2. The maximum gradient is not realized at the entrance to the nozzle’s minimum orifice, but at a certain distance from this entrance (curve 2 in Figure 2a). The gradient magnitude in the inlet section of the nozzle during the flow of the aqueous PEO solution is significantly lower than in the flow without PEO additives. This indicates that the hydrodynamic field induces changes in the polymer solution, which lead to a restructuring of the velocity field in such a way as to reduce the longitudinal velocity gradients. The longitudinal velocity gradient along the flow axis does not exceed 30 s⁻¹. There is a noticeable trend toward decreasing axial velocity gradients with increasing polymer molecular weight and its concentration in the solution.

Thus, the analyzed data indicate the specific features of the hydrodynamic field structure in the inlet section of the jet-forming nozzle of the hydroperforator during the flow of an aqueous PEO solution through it.

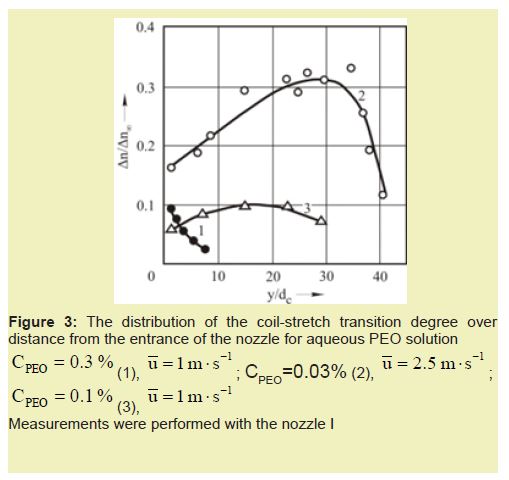

The observed changes in the structure of the hydrodynamic field can be associated with large distortions of the macromolecular coils induced by hydrodynamic field, leading to non-linear elasticity effects. The degree of the coil-stretch transition may be estimated from the value of the deformational factor , where

is the experimental flow birefringence value, while the

, is the limiting value of the flow birefringence calculated at the given concentration of polymer. The methods of

, calculations and experimental procedure of Dn measurements are given elsewhere.10

Results of the studies of the influence of hydrodynamic field on the polymeric solution are depicted in Figure 3. The value of deformational factor increases when approaching the entrance of the nozzle for the average flow rate equal to the critical value (curve 1) and reaches its maximum at rather high values (curve 2). The maximum position of the deformational factor

, at the entrance of the nozzle corresponds to the domain with maximal longitudinal velocity gradient (Figure 2a, curve 2).

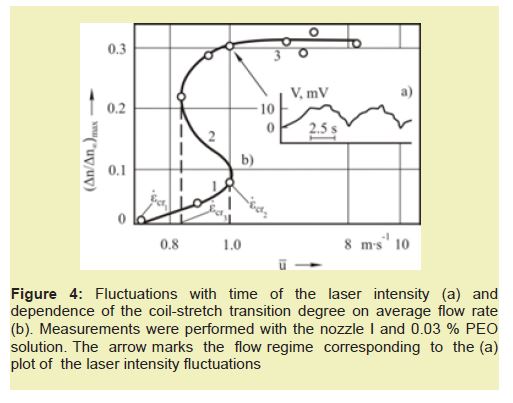

The flow becomes rather unstable after passing through the critical threshold, which can be seen from the plot of the laser beam intensity vs. time in Figure 4a the laser beam crossed the flow axis above the nozzele. The fluctuations are accompanied by the flow birefringence at the nozzle inlet. Hence, during the flow birefringence measurements, only maximal values at the given average flow rate of polymeric solution have been taken into consideration, as in the case of the velocity measurements. The obtained distribution of the deformational factor over the flow axis at the entrance of the nozzle capillary Figure 3 envisages the possibility of a high degree of coil-stretch transition under the free-converging flow conditions. The flow birefringence ratio attains the value of 0.33, which corresponds to ~60 % coil-stretch transition degree. Increasing the polymer concentration results in a decrease of the deformational factor (curve 3). Thus, for a 0.1 % PEO solution characterized by the , the

, ratio is equal to 0.1. Hence, in moderately concentrated (semi-dilute) solutions, the coil-stretch transition degree attains 30 %. Figure 4 envisages deformational behavior of macromolecules at the different flow rates. It can be seen that the

, vs. average flow rate dependence may be divided onto three domains. Domains 1 and 3 are characterized by a monotonic increase of the coil size with growth of the flow rate, while in the intermediate domain 2 the transition is rather sharp. From a comparison of Figures 2 and 4, it can be concluded that an increase of the

in the domain I is accompanied by growth of the longitudinal velocity gradient, which results in an increase of the size of the coils.

The values of the rate gradients arising at the entrance of the nozzle for polymeric solutions are somewhat lower than those for water at the same average flow rate. When attaining some critical velocity gradient , a sharp transformation of the size of the coils occurs. The sharp jump of the deformational factor with an increase of the average flow rate is an indication that the hydrodynamic field results in conformational instability of the macromolecules and the occurring coil-stretch transition is the first order phase transition. The phase transition results in a considerable readjustment of the velocity field leading to decrease of the longitudinal gradient which takes on the value

; the latter, however, must remain greater than

, which is the rate gradient when the flow birefringence zone is arising at the entrance of the nozzle model capillary, i.e., the

condition must hold. A further increase of

only slightly affects the deformational factor and the value of longitudinal gradient, see the domain 3. In that domain, considerable changes in velocity result in only slight variations of the longitudinal gradient (Figure 2,b, curve 2); this fact proves the non-linear dependence of the stretching degree on the rate gradient. According to Nikolis and Prigozhin,12 at least, the cubic non-linearity must occur.

The experimental data presented above clearly demonstrates that the water-polymer system under appropriate conditions of the converging flow exhibits self-organization with the negative feedback coupling. Indeed, increase of the longitudinal rate gradient results in the coil-stretch transition of the polymers, which, in turn, affects the flow structure in such a way that the longitudinal gradients become smaller. The gradients must remain greater than some critical value sufficient for the coil stretching, which is related to the macromolecule relaxation time by the following formula:

.13,14 Otherwise, the reverse stretch-coil transition occurs15 and macromolecules decrease their influence on the velocity field, which, in turn, results in a steep increase of the velocity gradient. This will lead to the coil-stretch transition and all the above processes will happen once again. Hence, the stable state is characterized by the minimal value of the velocity gradient which is sufficient for a sharp coil-stretch transition. Increase in the flow rate results in some additional growth of the deformational factor due to nonlinear effects (Figure 4, domain 3) sufficient for stability of the rate gradient field of the chosen polymeric system (Figure 2b, curve 2).

Hence, peculiarities of the free-converging flow of the polymeric solutions are associated with a high degree (~60 %) of reversible stretching of macromolecules caused by the hydrodynamic field and with an influence of the stretched macromolecules on the structure of the field. The experimental data obtained Tables 1 and 2 clearly indicate a strong deformational effect of the hydrodynamic field on the molecular coils of the polymer. This suggests that, during the flow of the polymer solution through the nozzle of the hydroperforator, polymer macromolecules are subjected to intense deformation caused by the longitudinal hydrodynamic field, as the velocity gradients generated in this process are sufficient to stretch the macromolecular chains.

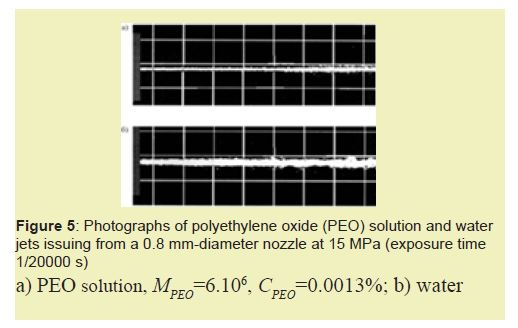

As a result, the water-polymer jet emerging from the jet-forming nozzle becomes effectively “reinforced” by the extended macromolecules. Part of the energy is expended on the structural reorganization of the flow,1 which leads to a decrease in the average velocity of the polymer solution jet.3 At the same time, the jet formation quality improves – the jet with polymer additives becomes more compact (with a smaller diameter) compared to the pure water jet Figure 5a. This contributes to an increase in the destructive capacity and, consequently, to an extension of the critical distance at which steel target destruction still occurs.

At present, the nature of the variation in the impact force of a water-polymer jet depending on the distance to the obstacle along the jet axis remains insufficiently understood. Even in the case of pure water jets, the literature presents conflicting viewpoints. Some researchers argue that the jet’s impact force on an obstacle decreases significantly with increasing distance from the nozzle exit. Others divide the total jet length into two characteristic regions: an initial region, where the impact force increases and reaches a maximum at a certain distance from the nozzle, and a subsequent main region, where the force remains practically constant.

For water-polymer jets, with the exception of the study,3 there is a lack of experimental data demonstrating the dependence of the impact force on the distance from the nozzle to the target. Therefore, the experiments described below were conducted to identify the dynamic features of water-polymer jets. Understanding these features may help reconcile existing contradictory experimental results. Resolving these discrepancies is essential for substantiating the mechanism behind the enhanced destructive capability of high-speed water-polymer jets, which is, in turn, necessary for determining the optimal parameters of an efficient casing perforation process in oil and gas wells.

The energy potential of the water-polymer jet was assessed by measuring the force it exerted on a steel (St3) plate equipped with strain gauges.

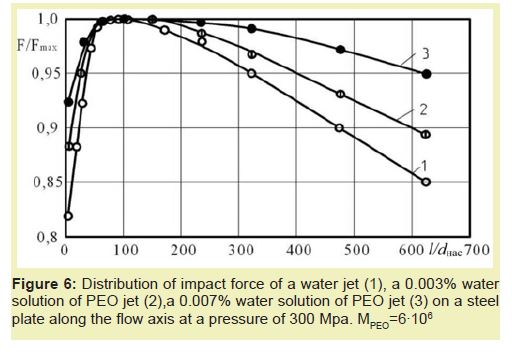

The results showing the development of the jet impact force with varying polyethylene oxide (PEO) content along the flow axis in dimensionless coordinates are presented in Figure 6. The experimental data obtained are described by at least two linear regions representing the variation in the jet’s impact force on the obstacle. It is evident that the maximum impact force, Fₘₐₓ, of the water-polymer jet on a flat obstacle depends on the PEO concentration in the solution and occurs within the dimensionless distance range of 30 < l/dnoz < 300, where l is the distance from the nozzle exit to the obstacle, and dnoz is the nozzle diameter.

A comparison of the impact force distribution along the jet axis Figure 6 with the jet’s structural features Figure 5а shows that the region l/dnoz < 100 corresponds to the initial part of the jet, while the region 30 < l/dnoz < 300 represents the main part of the jet.

The experimental data on the dynamics of the water-polymer jet fully explain the pattern of changes in its destructive properties depending on the distance between the obstacle surface and the nozzle outlet. This clarifies why, in some cases, the depth of the channel formed increases with the nozzle diameter, while in other cases, it decreases. Taking into account the data in Figure 6, it can be concluded that if the distance from the nozzle to the obstacle surface is shorter than the length of the initial section of the water-polymer jet, increasing the diameter of the nozzle outlet will lead to a decrease in the length of the channel formed during the hydroperforation of the well casing. However, if the distance approaches or exceeds the length of the main section of the water-polymer jet, the channel depth will increase with the nozzle diameter, assuming constant pressure drop.

Thus, the obtained results allow us to conclude that the mechanism of the high destructive capacity of the water-polymer jet lies in the dynamic pressure exerted by the jet, which is "reinforced" by highly extended macromolecular chains under the influence of flow in the inlet zone of the jet-forming nozzle of the hydroperforator.

- 1. The conducted experiments demonstrate the determining role of the longitudinal velocity gradient in deforming molecular coils and the minor role of the shear velocity gradient. This is an important factor that must be considered when designing the geometry of hydroperforator nozzles and selecting operational parameters for casing hydroperforation in oil and gas wells using high-velocity water-polymer jets.

- 2. It has been established that the mechanism of the high destructive ability of the water-polymer jet is due to the dynamic pressure generated by the jet, which is "reinforced" by strongly extended macromolecular chains under the influence of extensional flow in the inlet area of the jet-forming nozzle.

- 3. Understanding the nature of the high destructive power of the polymer solution jet is essential for identifying optimal flow regimes, designing efficient hydroperforator nozzle configurations, and determining the maximum performance of the system.

None.

This Research Article received no external funding.

Regarding the publication of this article, the authors declare that they have no conflict of interest.

- 1. Pogrebnyak V, Shymansky V, Perkun I. The water-polymer method of hydroperforation of oil and gas wells. Trends Petro Eng. 2023;3(2):1-9.

- 2. Chornyi MI, Chornyi OM, Metoshop IM, et al. Heolohichni osnovy rozkryttia i vyprobuvannia produktyvnykh plastiv. Ivano-Frankivsk: IFNTUNH. 2013.

- 3. Pogrebnyak VG, Naumchuk NV. Hydrodynamic activity of polymers in high-speed flows. J Eng Phys Thermophys. 1995;68(1):138-140.

- 4. Pogrebnyak VG, Voloshin VS. Ecological technology of creating waterproof screens. Monograph. Donetsk, Ukraine: Knowledge; 2010:pp.482.

- 5. Tatarskii VB. Crystal Optics and the Immersion Method. Moscow: Mir. 1965.

- 6. Ki BM, ed. The Newest Methods for the Study of Polymers. Moscow: Mir. 1966.

- 7. Tsvetkov VN, Eskin VE, Frenkel SYa. Structure of macromolecules in solutions. Boston Spa: National Lending Library for Science and Technology. 1971.

- 8. Tsvetkov VN. Rigid-Chain Polymers: Hydrodynamic and Optical Properties in Solution. New York: Consultants Bureau (Plenum Press). 1989.

- 9. Tager AA, Vshivkov SA, Pridannikov NA. High molecular compounds. A. 1979;21(3):566.

- 10. Brestkin YuV, Agranova SA, Dyakonova NE, et al. High molecular compounds. B. 1989;31(11):844-846.

- 11. Pogrebnyak AV, Perkun IV, Pogrebnyak VG. Degradation of polymer solutions in a hydrodynamic field with a longitudinal velocity gradient. J Eng Phys Thermophys. 2017;90(5):1219-1224.

- 12. Nicolis G, Prigogine I. Self-organization in nonequilibrium systems: From dissipative structures to order through fluctuations. New York:Wiley. 1977.

- 13. De Gennes PG. Coil stretch transition of dilute flexible polymers under ultrahigh velocity gradients. J Chem Phys. 1974;60(12):5030-5042.

- 14. Pogrebnyak VG, Pisarenko AA. Deformation effects in case of a flow with stretching of polymer solutions. Turbulence and Shear Flow Phenomena, Santa Barbara, California. In: Banerjee S, Eaton JK, eds. New York; 1999:1345-1350.

- 15. Pogrebnyak VG, Chudyk II, Perkun IV. Solutions of polymers in the oil and gas technologies. In: Prospects for Developing Resource-Saving Technologies in Mineral Mining and Processing. Multi-authored monograph. Petrosani, Romania: Universitas Publishing. 2022:pp.110–294.